Wood Chippers from Woodland Mills

WC68 6" Wood Chipper: click or scroll - WC46 4" Wood Chipper: click or scroll

WC88 PTO Drive 8" Wood Chipper

WC88 PTO Drive 8" Wood Chipper

Woodland Mills is pleased to offer our newly designed and exclusive 8” PTO drive wood chipper with auto hydraulic feed. The WC88 was designed to offer acreage owners an economical and well engineered wood chipper. This is a serious wood chipper, with a huge 8” chipping capacity. It was built to be the best valued wood chipper in its class. From the powder coated structure, to its industrial pillow block / flange mount bearings and 4 “V” belt drive system, this wood chipper will exceed your expectations.

The WC88 operates on tractors with 30-100 HP. It utilizes a large 23” x 27” infeed hopper opening that tapers down to an 8”x8” opening where the 8.25” diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼” diameter and as large as 8” diameter can be fed through the WC88. To chip full 8” diameter logs, tractors with over 60 HP are required.

See below for more details, features, specifications and warranty.

Click on the images below to see a larger version.

NOTE: Additional shipping charges may be applicable in some areas. Please inquire prior to ordering.

Special Offer: A minimum discount (more depending on total package) of $100.00 is offered for any Woodland Mill chipper purchase paid by cash, wire transfer, Etransfer, or direct cash deposit to our account at any branch of Royal Bank of Canada ( bank details provided).

| Product # | Price | Description |

|---|---|---|

| G-26-915 | $3999.00 | For WC88 PTO Wood Chipper + $349 shipping to most locations in Canada Please note that if you pick up your wood chipper at our Prince George, BC location, you still pay $295 inbound factory freight as that is what we pay to bring a bulk shipment of wood chipper into Prince George from factory. |

| B-26-916 | $269.00 | WC88 Maintenance Kit includes belts, blades and bed plate |

| C-26-917 | $85.00 | Drive Belt Kit - set of 4 |

| D-26-918 | $49.00 | Bed Plate Kit |

| E-26-919 | $159.00 | Chipper Blade Set - 4 blades |

All the Facts

- Huge 8.25” diameter infeed roller

- Large 8”x8” in-feed opening

- Forward/Neutral & Reverse infeed roller operation

- Infeed roller speed control valve

- Self contained hydraulic system run off tractor PTO

- Direct drive hydraulic pump (no belt slipping)

- Hinged clamshell flywheel housing design for quick and easy blade changes.

- 4 reversible chipper blades

- 24” diameter / 1” thick / 120lb solid steel flywheel

- Flywheel speed of over 1,100 RPM for maximum airflow and minimal clogging

- 3/8” thick chipper housing

- 4 heavy duty cogged B series drive belts with automatic tensioning system

- 360 degree rotating discharge chute

- Folding infeed chute for minimum footprint during storage

- ½” thick steel chipper base with full adjustability to accommodate various size tractors

- Commercial quality / standard sized greasable bearings

- Hinged belt guard cover for easy access to the drive system

- Quick attach 3 point hitch system

- Chainsaw holder

- Powder coated finish

- Hydraulic hose line protectors

- 1 hour assembly time

- PTO shaft included

- Heavy duty 1,050 lbs overall design/weight

- 3 year warranty

HYDRAULIC INFEED SYSTEM

Branches are pulled into the WC88 via the large 8.25” diameter infeed roller. The roller is hydraulically driven via the chippers self contained hydraulic system. The roller is adjustable in direction and speed making it easy to feed branches of all shapes and sizes. The hydraulic pump is direct drive from the lower shaft, meaning there is no need to worry about wearing or loose drive belts. The roller down pressure may be adjusted via the two large springs ensuring it grabs branches and easily pulls them in, eliminating the need for manual feeding.

FLYWHEEL

The dynamically balanced 24” diameter / 1” thick / 120 lb solid steel flywheel runs on a 2” diameter shaft and is supported by 2 industrial and greasable flanged bearings. It features four CNC machined pockets to hold the reversible blades. The flywheel features four large fan blade paddles that spin at over 1,100 RPM ensuring maximum airflow.

dRIVE BELT SYSTEM

The drive belt system is encased by a ¼” thick steel guard which can quickly be rotated forward to access the drive system. Simply pull the pin at the top and the guard folds forward, providing quick and complete access to the entire drive system. The PTO shaft (included with chipper) connects from your tractor to the chippers lower 2” shaft. Four heavy duty cogged BX series drive belts run up to the flywheel main shaft. These belts are standard off the shelf replacement parts. They are automatically kept in proper tension via the self tensioning system. This system dramatically increases belt life, reduces belt slippage and saves the user from manually adjusting for belt tension. Changing belts are also made easy as the tensioning system can easily be pulled back out of the way allowing the belts to be changed out quickly.

Chipper blades

Chipper blades

The WC88 chipper utilizes four high quality hardened steel reversible chipper blades. These blades are 90 degrees apart and are offset from one another. They can be flipped to take advantage of having two cutting edges on one blade. Each blade is held onto the flywheel with two countersunk M10 bolts and locking nuts. Changing blades can be made very quickly thanks to the clamshell flywheel housing design. Simply undo one bolt and the upper flywheel housing rotates open, providing full access to the flywheel and chipper blades.

Folding Infeed Chute

The infeed chute on the WC88 wood chipper has a large 23” x 27” opening, making it easy to feed branches with multiple limbs effortlessly. The infeed chute can also be folded up which decreases the footprint of the chipper during storage or transport.

The opening in the flywheel housing is a large 8”x8” square making it quite easy to accept branches with several limbs. This reduces the need to trim your branches down before feeding them into the chipper.

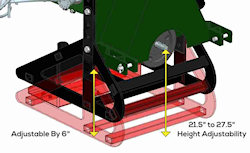

adjustable chipper base

adjustable chipper base

The WC88 chipper has a heavy duty chipper base made of 1/2″ thick laser cut steel plates. This base can be adjusted so that the PTO shaft sits at 21.5″ to 27.5″ off the ground to suit various tractor sizes. Simply hook the chipper up to your tractor and lift it up so it is suspended in the air. The four bolts that hold the base to the chipper housing can be removed and the base can be raised or lowered to suit your tractor configuration.

Discharge Chute

The discharge chute was designed to rotate 360 degrees by simply loosening the eye bolt and spinning it by hand to the desired angle. This makes it possible to direct the wood chips in any direction regardless of the location of the chipper. The end of the chute stands at 75” off of the ground, making it quite easy to direct the wood chips into the back of a truck or trailer if desired. Located at the end of the discharge chute is a rotating deflector, which allows further control of the location of the wood chips. Simply point it straight for maximum distance or angled down to deflect the chips directly down to the ground.

Assembly

The WC88 chipper will arrive in a steel crate and can be up and running in as little as one hour. The infeed chute and discharge chute have been removed during shipping to eliminate the possibility of damage. The chipper will require 20L of ISO 32 hydraulic oil in the tank which is not included, but can be purchased at most farm or hardware stores. Lastly, attach the PTO shaft that comes included and trim it to length for your tractor as per the manual if required.

warranty

The WC88 is covered by a full 3 year warranty against any manufacturing defects. If a part breaks, we simply ship you a new one from our fully stocked warehouse. Warranty parts can be shipped out same day or next day via Fedex. Wearing parts such as belts, bearings and blades are not covered under our warranty.

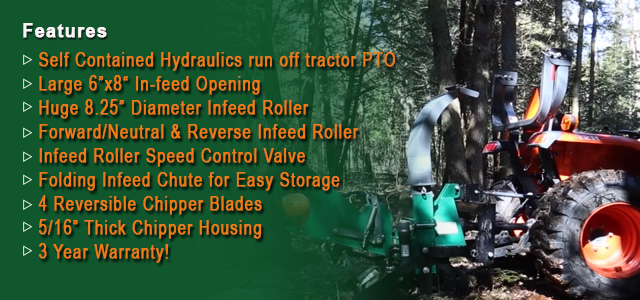

WC68 PTO Drive 6" Wood Chipper

WC68 PTO Drive 6" Wood Chipper

Woodland Mills is pleased to offer our newly designed and exclusive 6” PTO drive wood chipper with auto hydraulic feed. The WC68 was designed to offer acreage owners an economical and well engineered wood chipper. This is a serious wood chipper, with a huge 6” chipping capacity. It was built to be the best valued wood chipper in its class.

The WC68 operates on tractors with 20-50 HP. It utilizes a large 23” x 27” infeed hopper opening that tapers down to an 6” x 8” opening where the 8.25” diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼” diameter and as large as 6” diameter can be fed through the WC68. To chip full 6” diameter logs at full infeed speed, tractors with over 40 HP are required.

See below for more details, features, specifications and warranty.

Click on the images below to see a larger version.

NOTE: Additional shipping charges may be applicable in some areas. Please inquire prior to ordering.

Special Offer: A minimum discount (more depending on total package) of $80.00 is offered for any Woodland Mill chipper purchase paid by cash, wire transfer, Etransfer, or direct cash deposit to our account at any branch of Royal Bank of Canada ( bank details provided).

| Product # | Price | Description |

|---|---|---|

| G-26-920 | $3499.00 | For WC68 PTO Wood Chipper + $399 inbound factory freight to most locations in Canada Please note that if you pick up your wood chipper at our Prince George, BC location, you still pay $250 inbound factory freight as that is what we pay to bring these in to Prince George with a a bulk shipment for Woodland Mills products. |

| H-26-921 | $269.00 | Set of 4 blades, hydraulic pump belt and bed plate kit |

| J-26-922 | $215.00 | Set of 4 replacement blades |

All the Facts

- Huge 8.25” diameter infeed roller

- Large 6”x 8” in-feed opening

- Forward/Neutral & Reverse infeed roller operation

- Infeed roller speed control valve

- Self contained hydraulic system run off tractor PTO

- Hinged clamshell flywheel housing design for quick and easy blade changes.

- 4 reversible chipper blades

- 24” diameter / 3/4” thick / 100lb solid steel flywheel

- Flywheel speed of 540 RPM

- 5/16” thick chipper housing

- 360 degree rotating discharge chute

- Folding infeed chute for minimum footprint during storage

- 1/4” thick steel chipper base

- Commercial quality / standard sized greasable bearings

- Quick attach 3 point hitch system

- Powder coated finish

- Hydraulic hose line protectors

- 1 hour assembly time

- PTO shaft included

- Heavy duty 710 lbs overall design/weight

- 3 year warranty

Capacity

The WC68 operates on tractors with 20-50 HP. It utilizes a large 23” x 27” infeed hopper opening that tapers down to an 6” x 8” opening where the 8.25” diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼” diameter and as large as 6” diameter can be fed through the WC68. To chip full 6” diameter logs at full infeed speed, tractors with over 40 HP are required.

HYDRAULIC INFEED SYSTEM

Branches are pulled into the WC68 via the large 8.25” diameter infeed roller. The roller is hydraulically driven via the chippers self contained hydraulic system. The roller is adjustable in direction and speed making it easy to feed branches of all shapes and sizes. The hydraulic pump is belt driven from the main flywheel shaft. The roller down pressure may be adjusted via the two large springs ensuring it grabs branches and easily pulls them in, eliminating the need for manual feeding.

FLYWHEEL

The dynamically balanced 24” diameter / 3/4” thick / 100 lb solid steel flywheel runs on a 2” diameter shaft and is supported by 2 industrial and greasable flanged bearings. It features four CNC machined pockets to hold the reversible blades. The flywheel features four large fan blade paddles that spin at over 540 RPM.

Chipper blades

The WC68 chipper utilizes four high quality hardened steel reversible chipper blades. These blades are 90 degrees apart. They can be flipped to take advantage of having two cutting edges on one blade. Each blade is held onto the flywheel with four countersunk M10 bolts and locking nuts. Changing blades can be made very quickly thanks to the clamshell flywheel housing design. Simply undo one bolt and the upper flywheel housing rotates open, providing full access to the flywheel and chipper blades.

Folding Infeed Chute

The infeed chute on the WC68 wood chipper has a large 23” x 27” opening, making it easy to feed branches with multiple limbs effortlessly. The infeed chute can also be folded up which decreases the footprint of the chipper during storage or transport.

The infeed chute on the WC68 wood chipper has a large 23” x 27” opening, making it easy to feed branches with multiple limbs effortlessly. The infeed chute can also be folded up which decreases the footprint of the chipper during storage or transport.

The opening in the flywheel housing is a large 6”x8” square making it quite easy to accept branches with several limbs. This reduces the need to trim your branches down before feeding them into the chipper.

Discharge chute

The discharge chute was designed to rotate 360 degrees by simply loosening the eye bolt and spinning it by hand to the desired angle. This makes it possible to direct the wood chips in any direction regardless of the location of the chipper. The end of the chute stands at 75” off of the ground, making it quite easy to direct the wood chips into the back of a truck or trailer if desired. Located at the end of the discharge chute is a rotating deflector, which allows further control of the location of the wood chips. Simply point it straight for maximum distance or angled down to deflect the chips directly down to the ground.

Assembly

The WC68 chipper will arrive in a steel crate and can be up and running in as little as one hour. The infeed chute and discharge chute have been removed during shipping to eliminate the possibility of damage. The chipper will require 20L of ISO 32 hydraulic oil in the tank which is not included, but can be purchased at most farm or hardware stores. Lastly, attach the PTO shaft that comes included and trim it to length for your tractor as per the manual if required.

warranty

The WC68 is covered by a full 3 year warranty against any manufacturing defects. If a part breaks, we simply ship you a new one from our fully stocked warehouse. Warranty parts can be shipped out same day or next day via Fedex. Wearing parts such as belts, bearings and blades are not covered under our warranty.

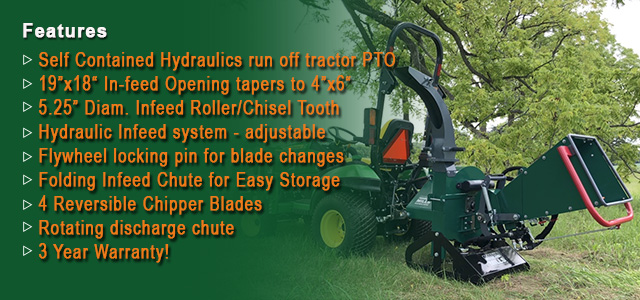

WC46 PTO Drive 4" Wood Chipper

WC46 PTO Drive 4" Wood Chipper

The Woodland Mills WC46 PTO drive wood chipper was specifically designed for sub-compact tractors with 15-30HP at the PTO. Featuring a hydraulic infeed system, the WC46 is capable of chipping up to 4” (10cm) diameter material. The WC46 is a good fit for customers with sub compact tractors that feature the following: 1) Rear PTO that spins at 540RPM 2) 15-30HP at the PTO 3) Ability to lift 550lbs (250kgs) at the 3 point hitch system

The WC46 operates on tractors with 15-30 HP at the PTO. It utilizes a large 19” x 18.5” (48cm x 47cm) infeed hopper opening that tapers down to a 4” x 6” (10 cm x 15 cm) opening where the 5.25” (13cm) diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼”(6mm) diameter and as large as 4” (10 cm) diameter can be fed through the WC46. To chip full 4” (10cm) diameter logs at full infeed speed, tractors with over 20 HP at the PTO is required.

See below for more details, features, specifications and warranty.

Click on the images below to see a larger version.

NOTE: Additional shipping charges may be applicable in some areas. Please inquire prior to ordering.

Special Offer: A minimum discount (more depending on total package) of $70.00 is offered for any Woodland Mill chipper purchase paid by cash, wire transfer, Etransfer, or direct cash deposit to our account at any branch of Royal Bank of Canada ( bank details provided).

| Product # | Price | Description |

|---|---|---|

| G-26-955 | $3099.00 | For WC46 PTO Wood Chipper + $399 inbound factory freight to most locations in Canada Please note that if you pick up your wood chipper at our Prince George, BC location, you still pay $250 inbound factory freight as that is what we pay to bring these in to Prince George with a a bulk shipment for Woodland Mills products. |

| G-26-956 | $249.00 | Set of 4 blades, hydraulic pump belt and bed plate kit |

| G-26-957 | $189.00 | Set of 4 replacement blades |

All the Facts

- 5.25” diameter infeed roller - chisel tooth

- Large 19"x18.5" in-feed opening tapering down to 4"x6"

- Forward/Neutral & Reverse infeed drive with variable speed

- Self contained hydraulic system run off tractor PTO

- Hinged clamshell flywheel housing design for quick and easy blade changes.

- 4 reversible chipper blades

- 18” diameter / 3/4” thick solid steel flywheel

- Flywheel speed of 540 RPM

- 5/16” thick chipper housing

- 360 degree rotating discharge chute

- Folding infeed chute for minimum footprint during storage

- 1/4” thick steel chipper base

- Commercial quality / standard sized greasable bearings

- Quick attach Tractor 3 point hitch system

- Powder coated finish

- Standard NPT Fittings & Valves

- 1 hour assembly time

- PTO shaft included - Shear Pin Protected

- Heavy duty 648 lbs overall design/weight

- 3 year warranty

Capacity

The WC46 operates on tractors with 15-30 HP at the PTO. It utilizes a large 19” x 18.5” (48cm x 47cm) infeed hopper opening that tapers down to a 4” x 6” (10 cm x 15 cm) opening where the 5.25” (13cm) diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼”(6mm) diameter and as large as 4” (10 cm) diameter can be fed through the WC46. To chip full 4” (10cm) diameter logs at full infeed speed, tractors with over 20 HP at the PTO is required.

The WC46 operates on tractors with 15-30 HP at the PTO. It utilizes a large 19” x 18.5” (48cm x 47cm) infeed hopper opening that tapers down to a 4” x 6” (10 cm x 15 cm) opening where the 5.25” (13cm) diameter hydraulically driven infeed roller grabs the branches and feeds them through the chipper. Branches as small as ¼”(6mm) diameter and as large as 4” (10 cm) diameter can be fed through the WC46. To chip full 4” (10cm) diameter logs at full infeed speed, tractors with over 20 HP at the PTO is required.

HYDRAULIC INFEED SYSTEM

Branches are pulled into the WC46 via the 5.25” (13cm) diameter infeed roller. The roller is hydraulically driven via the chippers self contained hydraulic system. The roller is adjustable in direction and speed making it easy to feed branches of all shapes and sizes. The hydraulic pump is belt driven from the main flywheel shaft. The roller down pressure may be adjusted via the two large springs ensuring it grabs branches and easily pulls them in, eliminating the need for manual feeding.

Branches are pulled into the WC46 via the 5.25” (13cm) diameter infeed roller. The roller is hydraulically driven via the chippers self contained hydraulic system. The roller is adjustable in direction and speed making it easy to feed branches of all shapes and sizes. The hydraulic pump is belt driven from the main flywheel shaft. The roller down pressure may be adjusted via the two large springs ensuring it grabs branches and easily pulls them in, eliminating the need for manual feeding.

FLYWHEEL

The dynamically balanced 18” (46cm) diameter, 3/4” (2cm) thick solid steel flywheel runs on a 2” (5cm) diameter shaft and is supported by 2 industrial and greaseable flanged bearings. It features four CNC machined pockets to hold the reversible blades. The flywheel features four large fan blade paddles that spin at over 540 RPM.

Chipper blades

The WC46 chipper utilizes four high quality hardened steel reversible chipper blades. These blades are 90 degrees apart. They can be flipped to take advantage of having two cutting edges on one blade. Each blade is held onto the flywheel with four countersunk M10 bolts and locking nuts. Changing blades can be done very quickly thanks to the clamshell flywheel housing design. Simply undo one bolt and the upper flywheel housing rotates open, providing full access to the flywheel and chipper blades.

The WC46 chipper utilizes four high quality hardened steel reversible chipper blades. These blades are 90 degrees apart. They can be flipped to take advantage of having two cutting edges on one blade. Each blade is held onto the flywheel with four countersunk M10 bolts and locking nuts. Changing blades can be done very quickly thanks to the clamshell flywheel housing design. Simply undo one bolt and the upper flywheel housing rotates open, providing full access to the flywheel and chipper blades.

Folding Infeed Chute

The infeed chute on the WC46 wood chipper has a 19” x 18.5” (48cm x 47cm) opening to feed branches into. The infeed chute can also be folded up which decreases the footprint of the chipper during storage or transport.

The infeed chute on the WC46 wood chipper has a 19” x 18.5” (48cm x 47cm) opening to feed branches into. The infeed chute can also be folded up which decreases the footprint of the chipper during storage or transport.

The opening in the flywheel housing is 4” x 6” (10cm x 15cm) square making it capable of accept branches with several limbs.

Discharge chute

The discharge chute was designed to rotate 360 degrees by simply rotating it with the two handles to the desired angle. This makes it possible to direct the wood chips in any direction regardless of the location of the chipper. The end of the chute stands at 66” (1.7m) off of the ground, making it quite easy to direct the wood chips into the back of a truck or trailer if desired. Located at the end of the discharge chute is a rotating deflector, which allows further control of the location of the wood chips. Simply point it straight for maximum distance or angled down to deflect the chips directly down to the ground or into a trailer.

Assembly

The WC46 chipper will arrive in a steel crate and can be up and running in as little as one hour. The infeed chute and discharge chute have been removed during shipping to eliminate the possibility of damage. The chipper will require 4.5 gallons (17L) of ISO 32 hydraulic oil in the tank, which is not included, but can be purchased at most farm or hardware stores. Lastly, attach the PTO shaft that comes included and trim it to length for your tractor as per the manual if required.

warranty

The WC46 is covered by a full 3 year warranty against any manufacturing defects. If a part breaks, we simply ship you a new one from our fully stocked warehouse. Warranty parts can be shipped out same day or next day. Wearing parts such as belts, bearings and blades are not covered under our warranty.